Unlike old times, contractors no longer wish to stay dependent on manual methods for constructing paver blocks. Manual process was time consuming and it also caused delays in construction projects leading to loss. But the availability of an automatic paver block machine has changed the dynamics of paver block construction. It is difficult for one to deliver precision and quality when producing paver blocks using hands. But now contractors need not worry about the same, as the availability of automated machines for paver block construction has made it easier for them to deliver high quality paver blocks within the required timeline. Switching to these machines is benefitting them in multiple ways which we are sharing in this blog.

No more compromise on precision and quality

One of the major reasons why contractors prefer choosing an automatic paver block machine is the quality. The need for accurate shape and precise paver blocks has increased. These road construction and pavement blocks are high in demand. But due to slow and poor manual handling, contractors often failed to deliver pavement blocks of accurate shape and size. This not only led to rejection of high amounts of paver blocks but it also caused them loss of raw materials and cost. That is why switching to automatic machines is a better resort in comparison to manually constructing these blocks. With the help of automatic machines one can deliver thousands of paver blocks of the same size and same shape without any problem. It also helps clients develop trust in contractors.

No more dependency on labors

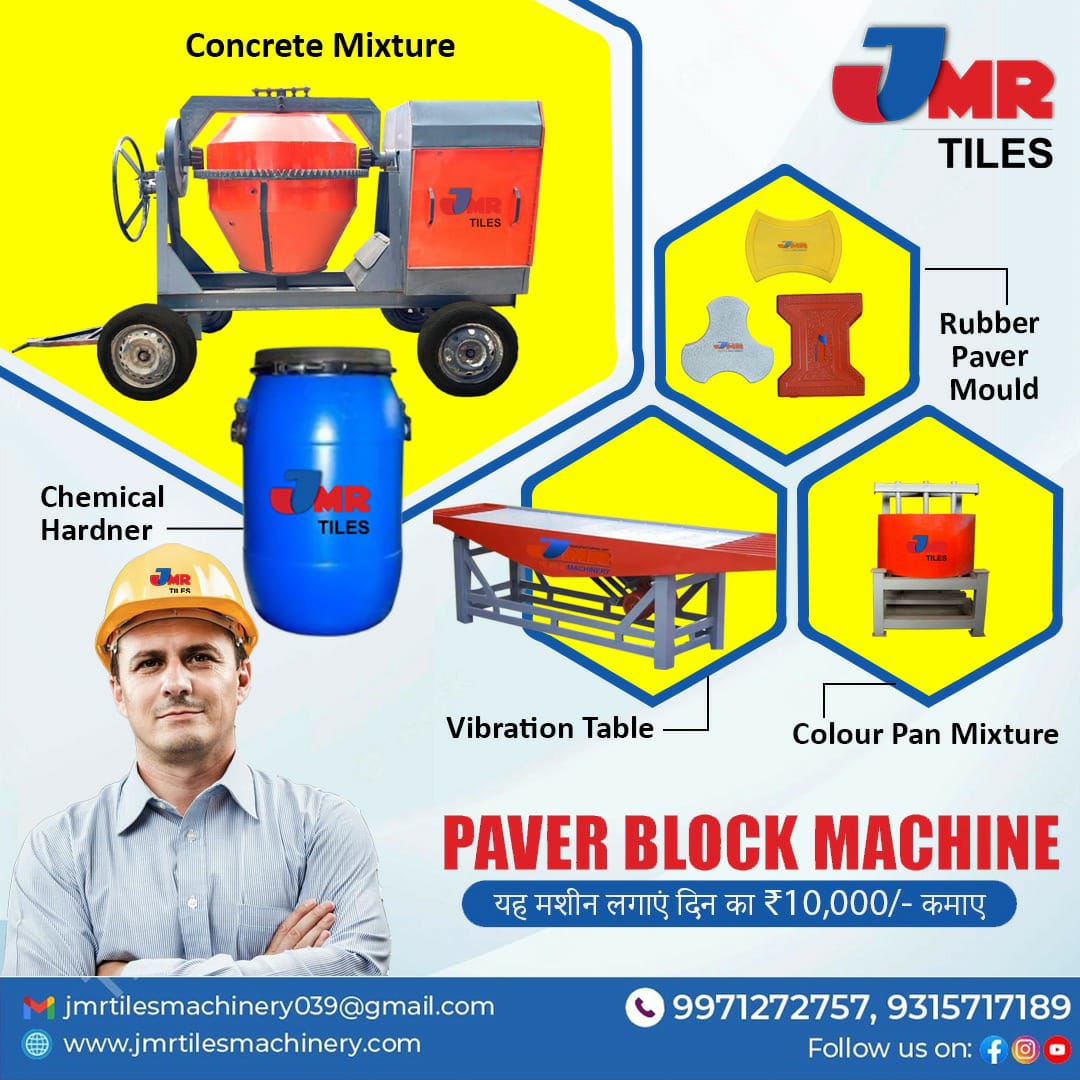

Manual work requires more labor which also increases the cost and dependency. But automatic machines help minimize this dependency by cutting the requirement of laborers. Be it mixing concrete or cement and other raw materials, or molding them or stacking them for production of paver blocks, all these tasks can be handled with the help of an automatic machine for paver block production. These machines come with several features which are easy to handle and operate making them an excellent choice for production of paver blocks.

Fast and timely delivery

Unlike the old times, contractors now no longer need to worry about the timeline for projects. Thanks to the availability of a technically advanced automatic paver block machine which allows fast and reliable production. These machines are a perfect fit for bulk production allowing one to deliver a large number of paver blocks according to client’s requirement. It allows contractors to handle multiple projects at a time without compromising on quality.

Conclusion

With all these benefits in terms of fast production and accurate shape and size of paver blocks, contractors are capable of delivering reliable quality paver blocks with ease. Use of automatic paver block machine will help contractors earn huge benefits. But contractors often find them in a dilemma when it comes to searching for reliable paver block machine manufacturers. Well, we at JMR Tiles & Machinery are here to help you with the same by delivering high quality automatic paver block manufacturing machines at cost-effective prices.