Every infrastructure or outdoor space relies heavily on high quality paving solutions. To get the best paver block, an automatic paver block machine, is what one requires. It enables one to manufacture a wide range of paver blocks that combine durability, precision, and visual appeal. These machines allow one to maintain consistency in shape, strength, and finish while meeting requirements from different clients. From residential pathways to heavy traffic areas, types of paver blocks vary and only automatic paver block production machines can help get these paver blocks. A few common types of paver blocks produced using these machines are shared below.

Zig Zag Paver Blocks for High Strength Areas

Zig zag paver blocks are among the most commonly used paver blocks in large scale projects. Their interlocking design provides excellent load distribution, making them suitable for areas that experience frequent movement and pressure. Using an automatic paver block machine, we ensure that each block fits perfectly with the next, creating a stable and long lasting surface. These pavers are widely used for industrial zones, parking areas, and road edges where strength is a priority.

Rectangular and Square Paver Blocks for Clean Layouts

Rectangular and square paver blocks are used in projects that demand a symmetrical appearance. These blocks are versatile and work well for footpaths, residential driveways, garden walkways, and commercial landscapes. Automation allows us to control dimensions accurately, resulting in sharp edges and smooth surfaces. Their simple design makes installation easier and quicker while offering flexibility in laying patterns.

Designer Paver Blocks for Aesthetic Appeal

For projects where appearance matters as much as strength, designer paver blocks are an excellent choice. Automatic machines help us create visually appealing designs with precise detailing and uniform color distribution. These blocks are often used in hotels, resorts, villas, public parks, and premium residential projects. The automation process ensures that even complex designs maintain consistent quality.

Heavy Duty Paver Blocks for Industrial Use

Some applications demand paver blocks that can withstand heavy loads and constant wear. Industrial yards, warehouses, ports, and logistics hubs require blocks with higher compressive strength. An automatic paver block machine enables us to produce heavy duty pavers with dense compaction and superior strength. By maintaining strict control over raw material ratios and vibration levels, we ensure that these pavers perform reliably even in demanding environments.

How Does an Automatic Paver Block Machine Make a Difference?

The use of an automatic paver block machine improves efficiency, reduces manual errors, and ensures repeatable quality. We are able to manufacture multiple types of paver blocks without frequent setup changes, which saves time and enhances productivity. Automation also supports scalability, allowing us to fulfill both small and large orders with equal consistency.

Conclusion

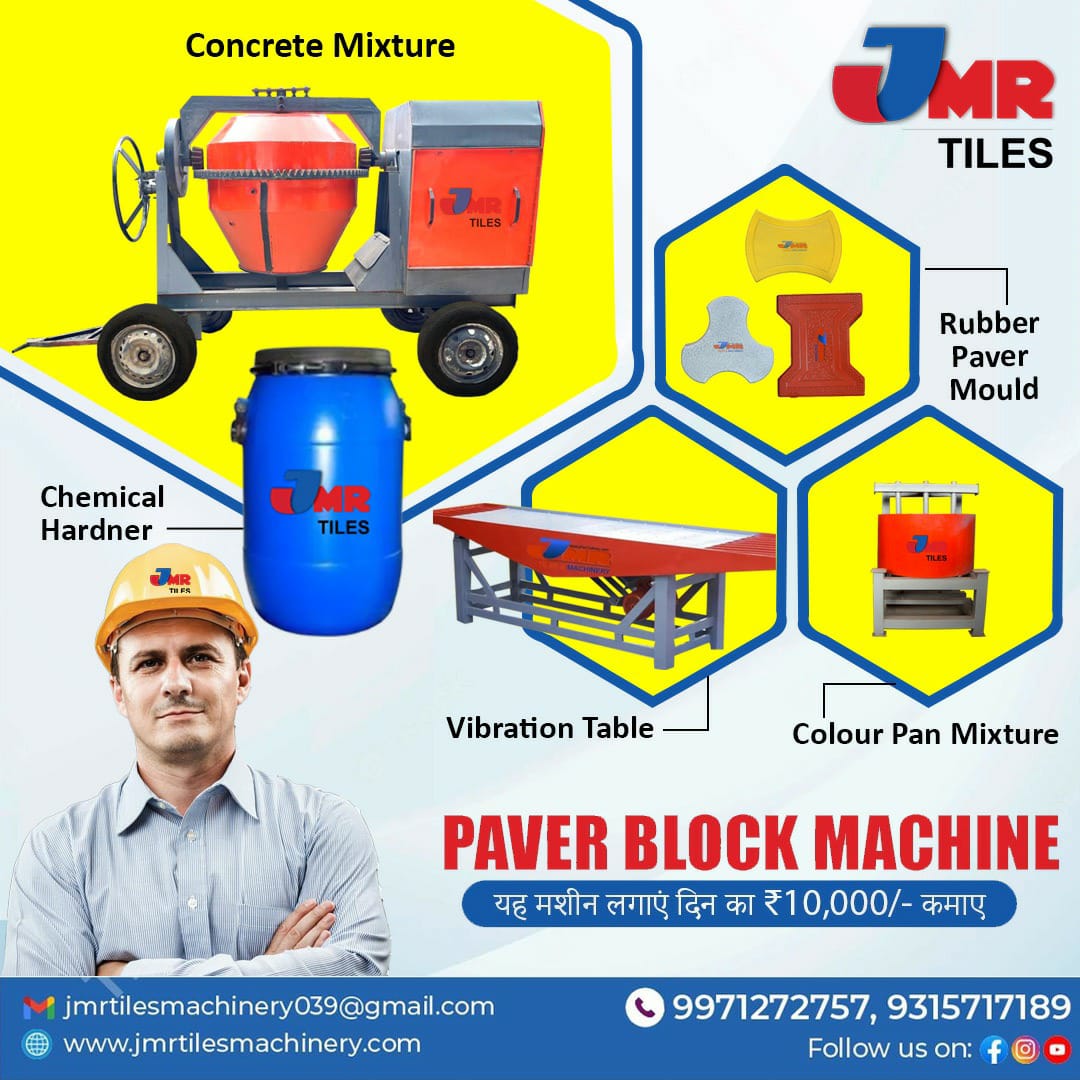

The variety of paver blocks that can be produced using automated technology offers support to different construction and landscaping projects. From functional industrial blocks to decorative designs, each type serves a different purpose while meeting high quality standards. At JMR Tiles & Machinery, we are fully focused on delivering reliable paver block manufacturing solutions in the form of automatic paver block machines to support paver block manufacturing business.